Maintenance Technician: Turn Machinery Into a Career

Request Information

All fields using an asterik (*) are required.

If you enjoy working with your hands, building things, and getting dirty, a career in the trades may be right for you. Learn all about the diverse world of maintenance technology, what maintenance tech jobs look like, and how to become a maintenance technician.

Why Industrial Maintenance?

Industrial maintenance is an overarching act of keeping machinery used in a variety of professional settings running. Maintenance technicians are effective mechanics specializing in large-scale machinery. However, there are a number of jobs that fall into the world of industrial maintenance. These can include but are not limited to:

- Industrial Maintenance Mechanic

- Industrial Machinery Mechanic

- Maintenance Technicians

- Machine Mechanic

- Machine Adjuster

Each role is unique. For example, a mechanic may be responsible for installing and dismantling equipment, whereas a technician may only be in charge of repairs and upkeep. These roles will vary depending on the organization you work for.

Industrial maintenance touches a variety of industries and enterprises because it encompasses most large-scale machinery. This means there are likely jobs available across industries.

What Does a Maintenance Technician Do?

What Does a Maintenance Technician Do?

According to the U.S. Bureau of Labor Statistics (BLS) industrial machinery mechanics and machinery maintenance workers maintain and repair factory equipment and other industrial machinery, such as conveying systems, production machinery, and packaging equipment. 1

According to the OnetOnline, some typical job duties of industrial machinery mechanics and machinery maintenance workers can include:

- Repair or maintain the operating condition of industrial production or processing machinery or equipment

- Disassemble machinery and equipment to remove parts and make repairs

- Repair or replace broken or malfunctioning components

- Reassemble equipment after completion of inspections, testing, or repairs

- Record production, repair, and machine maintenance information

- Inspect or test damaged machine parts

- Analyze test results, machine error messages, or information obtained from operators to diagnose equipment problems

- Clean and lubricate equipment or machinery

- Move machinery and equipment

- Set up and operate machines, and adjust controls to regulate operations

A major difference between industrial maintenance mechanical job descriptions and those of machinery maintenance workers is the level of repairs, according to the BLS.1 Maintenance mechanics do basic maintenance and repairs on machines. They clean and lubricate machinery, perform basic diagnostic tests, check the performance of the machine, and test damaged machine parts to determine whether major repairs are necessary. Major repairs are typically performed by an industrial maintenance mechanic.

Maintenance Technician Skills

While many skills to work in industrial maintenance will be learned both on the job and in formal training, there are some inherent skills that may make you more suited for the job. Just like someone working in medicine should not be afraid of blood, some qualities make for a better industrial maintenance worker.

According to O*NET Online, a website managed by the U.S. Department of Labor, here are some skills and qualities that an industrial machinery mechanic may possess:2

- Troubleshooting — Determining causes of operating errors and deciding what to do about it.

- Quality Control Analysis — Conducting tests and inspections of products, services, or processes to evaluate quality or performance.

- Equipment Selection — Determining the kind of tools and equipment needed to do a job.

- Complex Problem Solving — Identifying complex problems and reviewing related information to develop and evaluate options and implement solutions.

- Judgment and Decision Making — Considering the relative costs and benefits of potential actions to choose the most appropriate one.

- Information Ordering — The ability to arrange things or actions in a certain order or pattern according to a specific rule or set of rules (e.g., patterns of numbers, letters, words, pictures, mathematical operations).

- Problem Sensitivity — The ability to tell when something is wrong or is likely to go wrong. It does not involve solving the problem, only recognizing there is a problem.

- Inductive Reasoning — The ability to combine pieces of information to form general rules or conclusions (includes finding a relationship among seemingly unrelated events).

- Selective Attention — The ability to concentrate on a task over a period of time without being distracted.

Why Become a Maintenance Technician

Why Become a Maintenance Technician

According to the BLS, the growth of industrial mechanic jobs can be attributed to the growing popularity of automated manufacturing machinery. The continued adoption of automated manufacturing machinery is expected to create jobs for these workers, as they will be needed to help keep machines in good working order. The use of automated conveyors to move products and materials in factories is likely to be an area of high demand for these workers because the conveyor belts, motors, and rollers need regular care and maintenance.4

How to Become a Maintenance Technician

There are a few pathways to becoming a maintenance technician, but here are some common steps for how to prepare for this career field.

- Get educated. A GED or high school diploma is generally recommended to become a maintenance technician but additional schooling may be helpful. You can attend a certificate of achievement program at a community college or vocational school to obtain hands-on training for an entry-level position. Obtaining a certificate could make you more competitive when searching for your first maintenance technician job.

- Continue to hone your skills. Industrial maintenance is a varied career. Continued work experience and ongoing education may help.

Industrial maintenance certification does not require an apprenticeship but it is an option.

Can I Study to become an industrial machinery mechanic Online?

Working as an industrial machinery mechanic is a hands-on job. You’ll need to learn how to properly care for and maintain major machinery, which is something that should be practiced as well as studied in theory. It is unlikely you can complete a Maintenance Technician program online.

How to Choose a Maintenance Technician Program

Choosing a Maintenance Technician program to attend is a big decision and every school is going to say their program is the best. It’s important that you evaluate different programs to make sure they fit your needs and will help your individual career goals.

Some things you may want to look for when choosing a maintenance technician program include:

- Small class sizes. You will be learning how to handle large machines and electricity. Individual attention from your instructor can help ensure safety and better mastery.

- Hands-on training. Whether you are cleaning, lubricating, or starting, it’s important that you have time to practice those skills hands-on.

- Externships or career training. Most programs include an opportunity to learn in the real world before you even graduate! You’ll gain an impressive experience that looks great on your resume.

- Cost. Education is a major investment, but it’s an investment in your future. At Carrington College and many other institutions, we participate in most financial assistance programs, both federal and state, as well as private financing. Student loans, grants, and scholarships are available to those who qualify. For complete information on current tuition costs, please see the academic catalog.

What Will I Learn in a Maintenance Technician Program at Carrington College?

There are a variety of courses you can take in Carrington College’s Maintenance Technician program. Some sample courses you may take include:

IT101 Basic Industrial Electricity This seven-part course discusses the elements and applications of electricity that are common to any industrial facility. In strict accordance with the National Electric Code, this course will introduce students to electrical theory with an emphasis in those energy sources developed for commercial and manufacturing use.

IT201 Programmable Logic Controllers This course presents basic concepts and applications of PLCs such as the PLC language, performing installation and diagnostic functions, using program tools, basic communications, and logic operations. The practical instruction of this course is performed with Allen Bradley equipment and RSLogix software, both of which are predominantly used within the manufacturing industry.

IT120 Fluid Power This course presents basic concepts and operation of fluid power, demonstrating knowledge in maintenance, safety, and troubleshooting. Students will perform fluid power operations with the use of hydraulic power systems, symbols and schematic interpretation, industrial hydraulics, pressure control valves, directional control valves, check valves, flow control valves, actuators, pumps, oil conditioners, and measuring instruments.

Learn More About Maintenance Technician Training at Carrington College

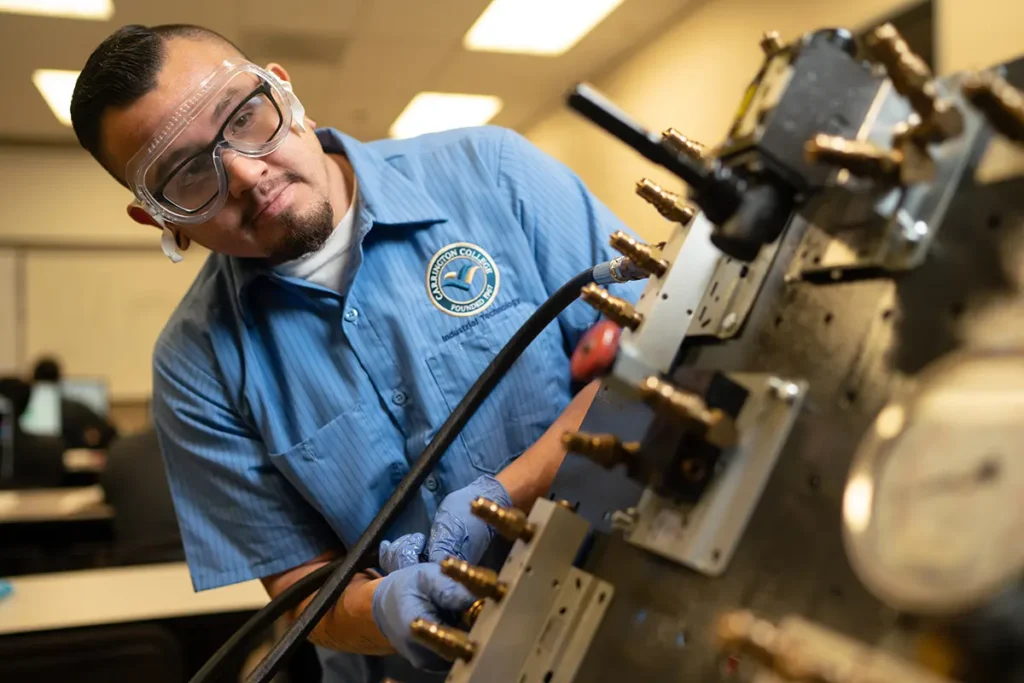

Maintenance Technician at Carrington College is taught by faculty with real-world experience at our Trades Education Center in Phoenix. Students use our facilities to get hands-on experience in how to work with different machinery components.

Learn more about the Maintenance Technician program and request more info.

Sources:

- www.bls.gov/ooh/installation-maintenance-and-repair/industrial-machinery-mechanics-and-maintenance-workers-and-millwrights.htm#tab-2

- www.onetonline.org/link/summary/49-9041.00

- www.marketwatch.com/story/manufacturing-employment-in-the-us-is-at-the-same-level-of-69-years-ago-2019-01-04

- www.bls.gov/ooh/installation-maintenance-and-repair/industrial-machinery-mechanics-and-maintenance-workers-and-millwrights.htm#tab-6

- www.bls.gov/ooh/installation-maintenance-and-repair/industrial-machinery-mechanics-and-maintenance-workers-and-millwrights.htm#tab-5

- www.bls.gov/oes/current/oes499041.htm#st

Last Updated:

December 19, 2023

WANT TO LEARN MORE?

Request Information

All fields using an asterik (*) are required.